My bike club took a road trip up to Falun, in central Sweden to ride the new indoor velodrome built in a former factory space. As the volume of the space prevented construction of a proper 250m regulation 'drome, the group behind the project settled for a smaller 190m oval with relatively long straights and steeply banked (50 degrees) sharp corners. And by filling the space, (which was punctuated by columns) the site has no provision for any type of bleachers or public seating.

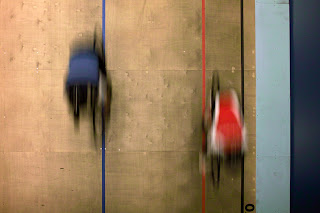

My bike club took a road trip up to Falun, in central Sweden to ride the new indoor velodrome built in a former factory space. As the volume of the space prevented construction of a proper 250m regulation 'drome, the group behind the project settled for a smaller 190m oval with relatively long straights and steeply banked (50 degrees) sharp corners. And by filling the space, (which was punctuated by columns) the site has no provision for any type of bleachers or public seating.All these drawbacks made me somewhat skeptical of the project. But after participating in the weekend-long course, led by club member and local resident Alf, I have to say I am an enthusiastic supporter of the effort, and would love to see a similar development in Göteborg. Riding in ovals is far from boring when you have a fine indoor facility such as this, and it requires a good deal of concentration to avoid spills.

I did take a tumble, or rather ran over a fellow who took a tumble directly in front of me, so have experienced plywood-burns. The experience was nothing to get terribly worried about, and will absolutely not prevent future endeavors on the track.

The visit did cause me to evaluate the total costs associated with having an indoor velodrome, which can be broken down into three broad categories: 1) the space, 2) the velodrome itself and associated costs (showers, bicycle maintenance and storage), 3) maintenance of the facility.

Of course, in the long run, 3 is going to be the biggest cost. The energy required to heat this immense volume is frightening to think about. As for initial costs, 1 vastly outstrips 2, especially if one is considering a vast span (no columns to disrupt views) and seats for a public. There is great architectural potential in an arena project, but the velodrome would most likely have to double up as a handball or basketball court, or ice rink, comprimising the interests of cyclists.

By reusing an existing facility, as they have in Falun, costs for 1 have been eliminated, allowing the much easier financing of 2. As for 3, hopefully the development will be such a great success that those operating costs will be covered by the site itself in a couple years. Time will tell.

One could skip 3 by proposing an outdoor velodrome, or a velodrome in an unheated shed, or simply under a roof, but that may not be such a popular solution. And in our post-industrial society, we are not lacking in vast empty factory buildings...