Tuesday, December 14, 2010

Wednesday, December 8, 2010

Wednesday, December 1, 2010

Deep Fried Turkey

I've been thinking about the process, though, and I'm not sure we can actually call the process "deep frying". After all, what happens with the bird is a lot different than what happens when you make french fries.

The surface area-to-volume-to-cooking time ratio is all messed up. Arguably, the skin is indeed deep fried, but what happens to the remainder of the bird is more akin to boiling or steaming.

I always bind up my bird with marine-grade stainless steel chain and shackles. Culinary chain. An effective, if to some rather off-putting method of securing the bird.

I always bind up my bird with marine-grade stainless steel chain and shackles. Culinary chain. An effective, if to some rather off-putting method of securing the bird. I don't have a proper "turkey fryer," but this 25 liter pot and paella burner work just fine. It takes a while to get the oil up to temperature. The end of the chain is secured in some sort of stick across the top of the pot.

I don't have a proper "turkey fryer," but this 25 liter pot and paella burner work just fine. It takes a while to get the oil up to temperature. The end of the chain is secured in some sort of stick across the top of the pot. The result. This year I tried something a little different. It was frightfully cold outside, and folks were getting antsy, so we put the bird in at 150 degrees celsius (300 F) rather than wait for it to reach 170. We then watched the temperature drop to about 110, and let the 5.6 kg bird sit in there for about 45 minutes. The lower temperature explains the coloring: maybe a little pale. The meat was great, though! And like I mentioned before, I'm not sure it's really deep frying. The oil never gets back to a temperature where it risks burning the skin. Really, the skin is shocked by the hot oil, and then the bird and the oil slowly approach equilibrium, closer to 100 degrees and well below frying temperature.

The result. This year I tried something a little different. It was frightfully cold outside, and folks were getting antsy, so we put the bird in at 150 degrees celsius (300 F) rather than wait for it to reach 170. We then watched the temperature drop to about 110, and let the 5.6 kg bird sit in there for about 45 minutes. The lower temperature explains the coloring: maybe a little pale. The meat was great, though! And like I mentioned before, I'm not sure it's really deep frying. The oil never gets back to a temperature where it risks burning the skin. Really, the skin is shocked by the hot oil, and then the bird and the oil slowly approach equilibrium, closer to 100 degrees and well below frying temperature.

Tuesday, November 23, 2010

Falun velodrome visit

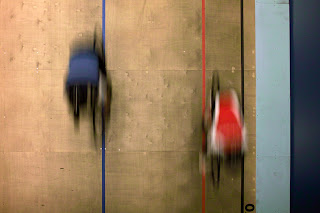

My bike club took a road trip up to Falun, in central Sweden to ride the new indoor velodrome built in a former factory space. As the volume of the space prevented construction of a proper 250m regulation 'drome, the group behind the project settled for a smaller 190m oval with relatively long straights and steeply banked (50 degrees) sharp corners. And by filling the space, (which was punctuated by columns) the site has no provision for any type of bleachers or public seating.

My bike club took a road trip up to Falun, in central Sweden to ride the new indoor velodrome built in a former factory space. As the volume of the space prevented construction of a proper 250m regulation 'drome, the group behind the project settled for a smaller 190m oval with relatively long straights and steeply banked (50 degrees) sharp corners. And by filling the space, (which was punctuated by columns) the site has no provision for any type of bleachers or public seating.All these drawbacks made me somewhat skeptical of the project. But after participating in the weekend-long course, led by club member and local resident Alf, I have to say I am an enthusiastic supporter of the effort, and would love to see a similar development in Göteborg. Riding in ovals is far from boring when you have a fine indoor facility such as this, and it requires a good deal of concentration to avoid spills.

I did take a tumble, or rather ran over a fellow who took a tumble directly in front of me, so have experienced plywood-burns. The experience was nothing to get terribly worried about, and will absolutely not prevent future endeavors on the track.

The visit did cause me to evaluate the total costs associated with having an indoor velodrome, which can be broken down into three broad categories: 1) the space, 2) the velodrome itself and associated costs (showers, bicycle maintenance and storage), 3) maintenance of the facility.

Of course, in the long run, 3 is going to be the biggest cost. The energy required to heat this immense volume is frightening to think about. As for initial costs, 1 vastly outstrips 2, especially if one is considering a vast span (no columns to disrupt views) and seats for a public. There is great architectural potential in an arena project, but the velodrome would most likely have to double up as a handball or basketball court, or ice rink, comprimising the interests of cyclists.

By reusing an existing facility, as they have in Falun, costs for 1 have been eliminated, allowing the much easier financing of 2. As for 3, hopefully the development will be such a great success that those operating costs will be covered by the site itself in a couple years. Time will tell.

One could skip 3 by proposing an outdoor velodrome, or a velodrome in an unheated shed, or simply under a roof, but that may not be such a popular solution. And in our post-industrial society, we are not lacking in vast empty factory buildings...

Monday, November 15, 2010

I've Got a Good Feeling About This

You've probably seen this video clip by now. It's a fairly amazing feat, but as Chris Jones explains, the contestant's reasoning leads to a fairly certain answer. As an experiment, I explained the game and the situation with this puzzle in three separate classes I taught today, with between one and six students each. With a little prodding, (circling the _'__ and _) each group was able to solve the puzzle within a couple minutes. These are groups of non-native English speakers, and certainly not big English-language puzzle fans. All the groups looked at it as an impossible task, but realized it wasn't as difficult as it seemed at first. An interesting reflection on possibility and appearances.

Friday, November 12, 2010

Apple Pie in an Omelette Pan

Anyway, today I had an epiphany while grilling a sandwich in my skillet. Of course! A skillet is basically a pie pan with a handle on it. So I set about trying with an apple pie in my omelette pan.

Shoe-wax lipbalm

After coming home, I decided to compare the labels more closely. Indeed, both my "universal lederbalsam" and Decubal Dry Spots Balm share almost their entire ingredients list:

After coming home, I decided to compare the labels more closely. Indeed, both my "universal lederbalsam" and Decubal Dry Spots Balm share almost their entire ingredients list: Beeswax (cera alba), lanolin, paraffinum liquidum (petroleum jelly), petrolatum, and castor oil (ricinus communis oil) are the basic components in both the shoe wax, selling for €80 per liter (note the price tag on mine was in Swedish kronor, making it actually significantly cheaper than the suggested retail price), and the lip balm, which at 65 kr for 30ml makes it about €230 per liter. It's hard to say what the exact proportions of the two compounds are, but they have a similar texture and odor. I suppose the Decubal has more lanolin, which can't be cheap. (Unrelated: In Sweden there's a whole ad campaign based on the premise that "cheap" sounds like "sheep" in English. Ridiculous.)

Beeswax (cera alba), lanolin, paraffinum liquidum (petroleum jelly), petrolatum, and castor oil (ricinus communis oil) are the basic components in both the shoe wax, selling for €80 per liter (note the price tag on mine was in Swedish kronor, making it actually significantly cheaper than the suggested retail price), and the lip balm, which at 65 kr for 30ml makes it about €230 per liter. It's hard to say what the exact proportions of the two compounds are, but they have a similar texture and odor. I suppose the Decubal has more lanolin, which can't be cheap. (Unrelated: In Sweden there's a whole ad campaign based on the premise that "cheap" sounds like "sheep" in English. Ridiculous.)Anyway, something to ponder.

Wednesday, November 10, 2010

Product review: Sugru part 2

One of the accessories sold for this camera is an external optical virefinder, an overpriced little plastic thing. I made my own from a flea market camera with the same field of view, a dead flash, hobby store brass, leather, and Sugru.

By this time I had learned a little bit about the material, and feel that this was a better success than my sauce pan repair. By letting the Sugru cure just a few minutes after opening the package it becomes much easier to mold. Most shapes are best created from a base sausage-type form, which can then be formed as it hardens over the next ten or fifteen minutes. Sugru also acts as an excellent putty for filling cracks and imperfections. The grip I added to the camera was smoothed and shaped with a stainless steel ruler, and looks like a commercial product. The viewfinder is more clumsy, but with the Sugru is now well-protected.

The material hardened quickly and the camera and viewfinder are now ready for use.

Tuesday, November 9, 2010

Pear clafoutis

Above: a buttered skillet, with ten smallish pear halves fanned out. Peel the pears, and use the end of the peeler to remove the core once halved.

Above: a buttered skillet, with ten smallish pear halves fanned out. Peel the pears, and use the end of the peeler to remove the core once halved.In the blender I've got 1 1/4 C of dairy: in this case half buttermilk and half whole milk. Crack in three eggs, then add 1/3 C of sugar and 1/3 C of flour, and a bit of vanilla. Blend!

Pour the mixture over the pears, and bake 30 min at 200 deg C (400 deg F).

Tuesday, November 2, 2010

Product review: Sugru part 1

Fortunately, I had a project waiting. This is a really nice 2L saucepan I picked up at a flea market here in town. Thick, robust stainless, possibly a sandwich bottom (one fellow I showed it to suggested it may have a layer of copper in the bottom), and a cracking bakelite plastic handle:

Normally I avoid any type of plastic handle on my pots and pans, since I like to be able to pop them from stove top to oven and back again at will. Since Sugru claims to be heat resistant to 180 deg C, I figured it was worth giving it a go to repair the handle.

Normally I avoid any type of plastic handle on my pots and pans, since I like to be able to pop them from stove top to oven and back again at will. Since Sugru claims to be heat resistant to 180 deg C, I figured it was worth giving it a go to repair the handle.My first impression of the material upon opening the package was that it was really too sticky and fluid to work with. It most certainly wouldn't support itself for any type of larger piece, at least in the state is is upon opening. I also realized that the volume of the little packet, while seemingly tiny, was really too much for my project.

I tried two different methods for this repair. First, I rubbed a small volume of Sugru in some of the smaller cracks near the handle, putty-like. Then I took a much larger volume and coated the handle around the larger cracks near the hole in the handle.

The Sugru was much harder to form and smooth than I had been expecting. It really is a fairly fluid consistency straight out of the packet. The final result is therefore kind of choppy, and not at all as professional-looking as I had hoped. But the cracks are indeed filled, and the handle has taken machine washings without any trouble so far. The Sugru-as-putty experiment was perhaps more successful, and I may attempt to re-do the handle entirely with this method in the future.

The Sugru was much harder to form and smooth than I had been expecting. It really is a fairly fluid consistency straight out of the packet. The final result is therefore kind of choppy, and not at all as professional-looking as I had hoped. But the cracks are indeed filled, and the handle has taken machine washings without any trouble so far. The Sugru-as-putty experiment was perhaps more successful, and I may attempt to re-do the handle entirely with this method in the future.

Friday, October 29, 2010

It's not a pizza until it comes out of the oven!

Thursday, October 21, 2010

Smith Tower Penthouse

Monday, October 18, 2010

The interesting work of John Ioannidis

(Graph courtesy of AAAS.) This is a frightening graph in many ways. We are on the cusp of a full-fledged energy crisis, yet the amount invested in energy research is a pittance compared to the money we're throwing away at medicine. As Ioannidis points out, the more money we throw at the field, the more phony results are likely to turn up. Still, it would make me a lot more comfortable to know that the field is given resources proportionate to its importance.

(Graph courtesy of AAAS.) This is a frightening graph in many ways. We are on the cusp of a full-fledged energy crisis, yet the amount invested in energy research is a pittance compared to the money we're throwing away at medicine. As Ioannidis points out, the more money we throw at the field, the more phony results are likely to turn up. Still, it would make me a lot more comfortable to know that the field is given resources proportionate to its importance.The other interesting element this article presents is whether the general trust the public has in science should be allowed to tarnish due to public exposure to Ioannidis's work. Doctors are held in special esteem by the general public, and for large swaths of the practice to be exposed as little more than fraud doesn't do much for the public acceptance of science (not to mention how it might poison the health-care debate in the US). Truly important issues of climate change, energy policy, stem-cell research, high-energy particle physics experiments, and science education can all be questioned by a science-questioning public (just look at the comments section of this NYT opinion column on climate change), but the public needs to maintain an open and tolerant mind, subject to change. I have no doubt that there is lots of lousy climate science out there, but the bulk and breadth of the total research combines to constitute fairly robust knowledge.

But the original article is of particular interest when one considers that the pharmaceuticals we're being fed unnecessarily end up right in the ecosystem. If we can trust her research, of course.

Magical Numbers

Tension cot

I was flipping through a Manufactum catalog yesterday and this cot, designed by Ole Gjerlov Knudsen in 1962 caught my eye. The use of natural material turnbuckles, as seen on a traditional bow saw, to form the tensioned tie beam in the structure is a clever use of traditional materials and technology. He designed a chair too, apparently.

I was flipping through a Manufactum catalog yesterday and this cot, designed by Ole Gjerlov Knudsen in 1962 caught my eye. The use of natural material turnbuckles, as seen on a traditional bow saw, to form the tensioned tie beam in the structure is a clever use of traditional materials and technology. He designed a chair too, apparently.Though the end results are quite different, a similar structural strategy is used in the LuxuryLite ultralight cot. This uses tensioned aluminum and carbon fiber poles instead of the traditional turnbuckle mechanism. The principle, using a tensioned tie beam, is the same.

It would be interesting to see further use of this principle in collapsing furniture. I've long been interested in the use of ratchet tie downs in other applications, and this would seem to be a natural use for them. Modern steel turnbuckles could also be used in this application.

Friday, October 15, 2010

Bridgestone MB-6 Project, Part 2

I visited the powder-coater with the bare frame this week, and was a bit taken aback by their new pricing. Really, the price is reasonable considering the work it takes, and to tell the truth I haven't been very satisfied with the work done for 200 kr. 800 kr, the current asking price, includes bead blasting and clear coating, luxuries previous junk bike projects have gone without. This is a vanity paint job more than anything, since it's not covering up any frame modifications. But the original paint was in such bad shape, I think I'll go ahead and do it. I'm going to blast the frame myself though, and save a bit on the total cost. They even had a pink, RAL 3015, which seems a popular color for bikes.

It seems a shame to spring for a new paint job without doing any frame modifications. The most obvious route, since it's going to be a singlespeed anyway, would be to put on some track ends. That way I'd avoid the trouble of gimmicky chain tensioners and whatnot. Still, I have a feeling this bike will live to experience another build, and I may want that derailleur hanger in the not-so-distant future. Also, the dropouts feature a couple fender/rack mounts, which will probably come in handy, and which are generally lacking from track ends if you don't drill and tap some of your own.

Another nice feature for a future build would be down-tube shifter mounts. These would add flexibility to any geared arrangement with derailleurs, and would allow the use of cheap and plentiful friction shifters either on the frame or on the bars. But again, the current build plan is to go singlespeed, and exposed and unused shifter bosses are even worse than exposed and unused canti-bosses, in my mind. So I think we'll forgo any additions or removals from this frame.

Is this frame really worth the trouble I'm putting into it? Of course I think so, for a number of reasons. Since I salvaged the frame, and am building the bike largely with the detritus of parts bins, my total cost won't be anywhere near that of a new bike, especially of the quality of this one. I believe any sort of adaptive reuse is a better solution for an old bike than the landfill, but there are particular bikes which represent especially good candidates for these types of projects. Road bikes from the 70s, 80s, and early 90s are widely appreciated. Quality, especially mid-market and up, was particularly good, industry standards still in use today were solidifying, and the geometry favored by builders was appropriate for a number of applications beyond that of road-racing.

Perhaps less appreciated today are the mountain bikes of the early 90s. There was a golden window, when mountain bikes were at the height of their popularity, that a number of factors came into play:

1 Geometry was more racing-oriented than that of most mountain bikes that came before, which means these bikes ride well over a variety of terrain. Also, they were not yet "suspension-specific", meaning the gap from bottom of the headtube to the tire falls is reasonable-appearing with normalish tires and fenders.

2 Standards in use today became firmly established: gone were the oddball U-brakes behind the bottom bracket and E-stays. Also, modern headset sizes (threaded 1", threadless 1 1/8") were common. Watch out for oddball headsets though! A good shop can help with things like facing a JIS-standard fork for industry standard races, but stems for threaded 1 1/8" forks or threadless 1" forks or anything 1 1/4" are hard to come by!

3 Taiwanese construction was established and relatively good by modern standards. Preferable exchange rates meant Western countries could buy relatively high-quality frames at low cost. Tube sets of complete double-butted chromoly and nice investment cast fittings were the norm even on mid-level bikes like this one. The aluminum bikes that stormed the market a few years after these are fine bikes, but they can't be as freely modified or repaired as bikes with steel frames.

4 Suspension forks hadn't yet entered the mainstream at the mid-level pricepoint, which automatically made these bikes a better all-around value than those that followed. Not having a suspension fork reduces the overall complexity of modifying these bikes for other use, as you don't have to spend time searching for finding out-of-production replacement parts. Fortunately, there are plenty of rigid replacement 1 1/8" forks available for those stuck with an obsolete fork.

The Bridgestone frame I am working on with this project benefits from all of the above. 26.2mm seatposts don't grow on trees, but otherwise almost everything on this frame is relevant today. The 1" threaded fork means I can pick from a variety of interesting stems, and cantilever brake bosses open up the world of modern and vintage cantis and V-brakes.

All that being said, it's not a lightweight:

Frame: 2342g

Fork: 882g

(with original paint)

Wednesday, October 13, 2010

The Levytator

This seems like a very practical solution for many adaptive reuse building projects when the building owner requires or desires increased accessibility for end users without compromising the architectural or cultural values of the original structure. The logistics of disembarking may prove challenging for some, especially since it differs so greatly from the experience of escalators of which we are so accustomed, and one can worry about crowding in the potentially dangerous staging area. The principle reminds me somewhat of funicular railways.

Tuesday, October 12, 2010

Corned Beef in a few weeks

Below you can see my preparation for beef corning.

I've got a lidded glass container I can keep the beef in while it seasons for three weeks. In the picture you can see that I've covered the beef with water to estimate the amount I'll need to keep it submerged. I measured the water (about 3 cups) as I decanted it into a small pot. As I heated the water, I determined that I needed about 1/4 C of course salt (I'm going roughly by Joy's recommendation here, though I've learned to cut the salt in half), which I stirred in just before the water reached a boil, and then poured it into the glass container. I've also seasoned the brine with a bay leaf, white peppercorns, allspice, mustard seed, cloves, and a couple tablespoons of sugar. It's cooling in the fridge right now, but this evening I'll free the beef of it's plastic wrap and submerge it in the brine. I use the stainless steel chain pictured in the bottom right (acquired at a marine supply shop) to keep the beef under the water level of the brine while it sits in the fridge from 2-4 weeks.

I've got a lidded glass container I can keep the beef in while it seasons for three weeks. In the picture you can see that I've covered the beef with water to estimate the amount I'll need to keep it submerged. I measured the water (about 3 cups) as I decanted it into a small pot. As I heated the water, I determined that I needed about 1/4 C of course salt (I'm going roughly by Joy's recommendation here, though I've learned to cut the salt in half), which I stirred in just before the water reached a boil, and then poured it into the glass container. I've also seasoned the brine with a bay leaf, white peppercorns, allspice, mustard seed, cloves, and a couple tablespoons of sugar. It's cooling in the fridge right now, but this evening I'll free the beef of it's plastic wrap and submerge it in the brine. I use the stainless steel chain pictured in the bottom right (acquired at a marine supply shop) to keep the beef under the water level of the brine while it sits in the fridge from 2-4 weeks.

Friday, October 8, 2010

Frugal Engineering

At the same time, I read in Newsweek that there will be 5 billion mobile phones in use next year, out of a global population of 7 billion. Considering the number of people either too young or too old to use mobile phones, that is a truly incredible statistic. Of course, the majority of those carrying mobile phones around the world use them for little more than calling or sending text messages. Phones like the Nokia presented in the first linked article offer these services and little else.

This is a frustrating use of resources. Sometimes I felt like I was the last person in Sweden to start using a mobile phone five or so years ago, but I couldn't really be convinced of the utility of carrying a device that could only make (expensive!) phone calls. When I bought my first mobile phone it had a decent camera on it, which was useful for note-taking, but I also very quickly learned to love Opera Mini, which gave me access to almost the entire internet through GPRS. This was a more monumental event than gaining access to the internet for the first time in college. Back in '96, the internet had the tiniest fraction of the world's information searchable, but by 2006 it was a different story altogether.

The point is, every mobile phone has the basic functions to allow access to the internet. They are by their very nature telecommunication devices, so network access shouldn't be a problem. They have displays, even if they are rudimentary, that can present text. And they have some sort of input device, a keypad. The internet is now a great depository for all manner of sounds, video, and images, but it is still largely driven and organized by text. That 5 billion people next year can have access to that information from almost anywhere is truly revolutionary. But can these simple phones access the internet? Are they provided with the software to make it possible? I certainly hope so.

Smart phones are great, but I think these not-so-smart phones could be truly earth-shattering.

Wednesday, October 6, 2010

Bridgestone MB-6 Project, Part 1

I love junk bike projects. Taking a bunch of old, abandoned parts and making something new, useful, and maybe even beautiful out if it can be a lot of fun. Of course, working with nice parts has it advantages, but the challenge presented by a pile of junk is unique.

I love junk bike projects. Taking a bunch of old, abandoned parts and making something new, useful, and maybe even beautiful out if it can be a lot of fun. Of course, working with nice parts has it advantages, but the challenge presented by a pile of junk is unique.This 1991 Bridgestone MB-6 may not be the finest salvaged bikee out there, but it is a tigged-in-Taiwan double butted Tange Chromoly frame with pretty decent geometry. It's actually pretty similar (probably identical, save for the size) to my MB-5, and like that bike, I plan to limit this build to a single gear. I perhaps too-hastily built it up for my cousin visiting last month, and it barely survived the 100km gravel race she rode it in. My main problem in that build, besides chain tension, were the frozen-in-the-frame bearings and stem wedge. Carrying it home from the bike club, I ran into a fellow with a high-pressure hose cleaning out the tram turnouts in the street, and had him clean the mud off of the thing. After about an hour at Veloform today, I left with a bare-naked frame and fork, ready for powder coating.

A local powder coater has had pretty reasonable rates for bike frames, which encourages one to experiment or modify a frame more than one would without a cheap and effective way of covering the frame up again. For example, my fixed-gear bike is a salvaged road bike with brazed-in track ends, replaced brake bridge, and removed down tube shifter mounts and brake cable stops. My wife's commute bike is an old mountain bike with down tube shift bosses added. I don't think I'll be doing any frame modifications to this bike, but it certainly needs paint.

Walking home from the shop today with the frame I ran into Patrik, carrying a repaired Surly Cross-check. We compared frame weights a bit, and can only conclude that this frame is a boat anchor. Of course, one only has to consider the 26.2 seatpost to realize that the tubes are a bit thicker than bike snobs may be used to...

But like I said, good geometry, a solid frame and rigid fork. It should be a fun bike.

A Whole Chicken

1 Breasts get used for fajitas or stir-fries, or are maybe marinated and grilled, and sliced and served alongside heaps of veggies and starches. At any rate, there are just the two of them, and they're usually not that big when I get them off of the whole chickens on offer here. But they'll provide the animal protein for a family meal at any rate.

2 Drumsticks get separated from the thighs and, and these together with the wings (and oysters, if I remember to dig them out) are marinated and roasted and served whole, or pan-fried, or thrown into a simple chicken stew. More flavor, and fat in these pieces, though they're filled with those cumbersome bones.

3 The carcass is really what we're working towards here. The other parts can get bought and used already prepared, but the carcass is special, especially in a country where canned chicken broth is unheard of. Here you're stuck with salty, suspicious bouillon cubes or doing it from scratch. I keep a big yogurt bin in the freezer I periodically fill with vegetable trimmings: the ends of onions and carrots and celery, and when I've got a chicken carcass (or back) to work with I throw it (trimmed of fat and skin) in the stock pot along with whatever's in the freezer. I usually get enough stock from this process to make a pot of soup and a batch of risotto.

There's nothing new in any of this, of course, but it does require a little planning ahead and a bit of time on the part of the cook. We're not a vegetarian household, but that doesn't mean we don't respect the animal or can't try to make the most of it while limiting our intake of animal protein. Making a chicken last three or four meals is just part of that philosophy.

Tuesday, October 5, 2010

Sunday, October 3, 2010

Pastry Cutter Improvement

"Oh yeah, biscuits. Need to do those more often."

By the way, why the cream of tartar? I'm guessing he was using some antiquated recipe before pre-blended baking powder was available? At any rate, I don't use cream of tartar, though I have found a source in Sweden: Curry House, in Haga has it in stock. I forget if they call it vinsten or cream of tartar, but at any rate you can't get it at the pharmacy anymore.

To incorporate the butter and flour in biscuits, or for pie crust, I've been using my stand mixer for the last number of years, because it's there and it works, and because I hated my pastry cutter. Maybe I've been using it wrong, but I didn't like the way the handle rotated in my hand, and the protruding nut on one side always dug into my skin. So the pastry cutter languished in a drawer, and every time I set about making a little batch of biscuits I'd fire up the Hobart, which seems like overkill.

I tried replacing the bolt with some stainless screws I had laying around from an earlier project, but the hole for the through-bolt was so big the screws didn't bite very well. So I decided to make a new handle.

I had some ash laying around, so I got out an appropriate knife, cleaned up its edge, and got whittling.

A little 240 sandpaper later and the handle was ready. I cut it off and rubbed some canola into the grain, followed by some beeswax, and then used the stainless screws to fasten the handle into the pastry cutter again.

A little 240 sandpaper later and the handle was ready. I cut it off and rubbed some canola into the grain, followed by some beeswax, and then used the stainless screws to fasten the handle into the pastry cutter again. The whole process was done before my potatoes finished boiling. And it didn't cost me a cent. And it will make using the pastry cutter a whole lot more pleasant. So why did I put it off for so long? These sorts of little projects can make life easier and more enjoyable, and aren't exactly a nuisance. And are in every way sustainable: I have repurposed a tool I found lacking rather than replacing or discarding it. This project will moreover enable me to use a simple hand tool over a complex and energy-demanding power tool when appropriate.

The whole process was done before my potatoes finished boiling. And it didn't cost me a cent. And it will make using the pastry cutter a whole lot more pleasant. So why did I put it off for so long? These sorts of little projects can make life easier and more enjoyable, and aren't exactly a nuisance. And are in every way sustainable: I have repurposed a tool I found lacking rather than replacing or discarding it. This project will moreover enable me to use a simple hand tool over a complex and energy-demanding power tool when appropriate.Fixing a broken or lacking tool is the sort of thing that should be second nature to us, but seems more and more to be a thing of the past. That I should be blogging about this mundane repair is on the surface ridiculous, but I believe we need to think more in terms of making do with what we have.

Oct. 5 update: I furthered refined the handle by rounding the hard edges visible in the above photo.

Ronde van Retaard Pictures

Friday, October 1, 2010

Clen-tador

Wednesday, September 29, 2010

Interesting links

Also, it will be interesting to see where this goes. Food pairing? Hmm.

A sensible trail bike

Here it is, pictured in the middle of a 42km mixed-terrain ride I did yesterday. The 38mm tires offer plenty of volume for rough trail surfaces, though as a rider you have to be more careful than you might riding fat 55mm tires. The cassette and chainring combo provides a broad gearing selection, and the funny handlebar offers plenty of hand positions with good control over the bike.

The ride was maybe 60% trails and gravel, with the remainder well-maintained asphalt, the latter primarily in a strong headwind. The bike performs well as set-up in most of these conditions. Admittedly, I sometimes wished for the comfort, predictability, and braking performance of my mountain bike, and on the ride home I maybe would have preferred my road bike, but I would never have taken either on the entire route.

Birthday Cassoulet

I had soaked a pound (450g) of white beans over night, the proper way, rather than my usual method of pushing them with boiling water. No appreciable difference, but the beans were ready to go first thing in the morning. I replaced the soaking water and added a nice can of tomatoes and let cook. Meanwhile, I roasted the meats, salted and peppered and dressed with olive oil under the broiler until nicely browned. When they were ready, I threw them in the pot, and turned the burner off to let them cook together on the residual heat. Meanwhile, two chopped carrots, two chopped onions, and three cloves of garlic got tossed in the rendered fat of the meat roasting pan and were thrown under the broiler for ten minutes or so. When they were ready I lowered the rack and turned the oven down to 125 C, put the veggies in the soup pot together with a healthy dose of thyme and a bay leaf. The whole pot got put in the oven with its heavy lid on tight for a couple of hours. I pulled it out, let it rest, and threw it in the fridge before my mid-day bike ride.

I had soaked a pound (450g) of white beans over night, the proper way, rather than my usual method of pushing them with boiling water. No appreciable difference, but the beans were ready to go first thing in the morning. I replaced the soaking water and added a nice can of tomatoes and let cook. Meanwhile, I roasted the meats, salted and peppered and dressed with olive oil under the broiler until nicely browned. When they were ready, I threw them in the pot, and turned the burner off to let them cook together on the residual heat. Meanwhile, two chopped carrots, two chopped onions, and three cloves of garlic got tossed in the rendered fat of the meat roasting pan and were thrown under the broiler for ten minutes or so. When they were ready I lowered the rack and turned the oven down to 125 C, put the veggies in the soup pot together with a healthy dose of thyme and a bay leaf. The whole pot got put in the oven with its heavy lid on tight for a couple of hours. I pulled it out, let it rest, and threw it in the fridge before my mid-day bike ride.Two hours before dinnertime I fished out the sausage and cut it up, and picked the duck meat off the bone, and threw the pot back in the oven at 125 C. A fine cassoulet.

Friday, September 24, 2010

Presenting Pocket Coffee

A New Solution to an Age-Old Problem

The outdoors-person has a wide variety of stoves, pans, and other kitchen-wares available for preparing an evening meal or a hearty breakfast in the wilderness. A long-distance hiker or bicycle tourist finds great comfort in a warm meal at the end of a difficult journey, but manufacturers currently ignore the needs of the more modest adventurer on a brief excursion.

Pity the poor day hiker in need of a fresh cup of coffee! This wretched soul has hither-to been forced to either bear the burden of an over-dimensioned camping cook-set, suffer the indignity and clumsiness of stale coffee from a vacuum flask, or go without.

Pocket Coffee to the Rescue

Utilizing an optimized, lightweight and simple low-pressure sideburner alcohol burning stove unit, compact pot with incorporated handle, and separate press mechanism with molded-in sip-lid, Pocket Coffee is a complete system for preparing a cup of coffee in the open air.

Nevermore must a brave day-tripper let a thirst for a piping-hot cup of Java go unsatiated.

A simple tool

Pocket Coffee's simple and proven alcohol burning stove is the heart of the pocket coffee concept. Once primed, the pan may be placed directly on the stove, eliminating the need for a separate pot stand. In normal conditions the little stove will bring 2.5dl of water to boil in mere minutes.

Robust construction

The Pocket Coffee stove and pot are are manufactured entirely of lightweight, tough, and heat-conductive stamped sheet aluminum. The press mechanism is injected-molded in food-safe plastic, with an aluminum coffee screen affixed to the under-side. The proven and inexpensive materials and production technique ensure that Pocket Coffee is fairly priced, and affordable to adventurers of all types.

Truly compact

With a packed size of 10cm in diameter and approximately 5cm in height, Pocket Coffee is truly compact, and with a total weight of less than 100 grams there is room for it in any pack or pocket. Indeed, Pocket Coffee weighs far less than any combination kit available on the market, and less even than an insulated vacuum flask.

The stove element sits snugly inside the press mechanism, protecting it from shakes and preventing rattling. The entire kit fits inside the accompanying pot.

A versatile piece of kit

Despite its name, the Pocket Coffee stove and pot can be used to prepare any warm beverage, powdered soup, or a single portion of porridge.

Pocket Coffee is suitable for use during simple day hikes, ski outings, day-long bicycle tours, or any other outdoor activity when a warm beverage might be appreciated. True minimalists may choose to use Pocket Coffee as their primary cooking kit during more prolonged expeditions, but that is not this product's intended use.

A product of its time

Today's informed and cosmopolitan outdoor enthusiasts refuse to settle for the outdated and clumsy solutions of yesteryear. Pocket Coffee allows connoisseurs the pleasure of a hot and freshly brewed cup of coffee anywhere with ease.

Thursday, September 23, 2010

Thoughts on cyclocross bikes

A simple equation for determining the appropriateness of a bicycle for a given terrain would be something like "tire width" x "gearing" / "rider fitness and skill". "Mountain bikes" tend to have much wider tires, around 50-60mm, and much lower gearing than "road bikes". The remaining differences, one can argue, are trivial, or related more to either tire width or gearing than to the terrain itself. For example, "road" brakes accommodate only "road tires" with little clearance for mud, fenders, or fatter tires. Rider fitness and skill are important to consider as well, however, because particularly fit or skilled riders can accomplish much more with a given bike than the bicycle itself might suggest.

Hybrid bicycles have always tried to run the middle ground, with broad gearing and mid-width tires, which has been a reasonable set-up for indeed most of the riding public riding most roads and trails together with most other people. The sneering from the bicycle community originates mainly in component snobbery and expectations about particular types of bikes in particular terrains. The problem really comes from the component manufacturers' side, which has steadfastly refused to produce quality parts not required for specific types of competition. Thus, a paucity of appropriate tires, and clumsy or aggressive mountain bike drivetrain parts have been part and parcel of the hybrid specification.

Some hybrids are arguably more successful at bridging the gap, such as the short-lived and rare Specialized Rock Combo and Bridgestone XO-1. Both of these bikes pursued the successful route of using 559mm rims, taking advantage of this size's comparatively wide variety of tires. The Specialized, using MTB drivetrain parts, achieved lower gearing, while the XO-1, using lighter road parts compromised with the acceptable low of 34/28. Both also abandoned the limiting flat bar in favor of more "road" bike style bars with multiple hand positions. Tire availability is really the most important factor in spec-ing bikes like this. Drivetrains and gearing are changed easily enough, but with canti-bosses fixed on the frame, changing rim diameter to match tire availability is another matter. Perhaps the most salient example of this problem was the doomed GT Tachyon and its proprietary 700D tire size. Without any replacement tires available, those bikes are sitting pretty useless now.

But things have changed in the past ten years. The popularity of "29-er" mountain bikes has meant a burst of variety on the wide-end of of the 622mm rim diameter tire selection. Tubular tires are gaining popularity even for smaller wheeled mountain bikes (more a curiosity than anything relating to the theme of this post) and component manufacturers are starting to realize the potential for wide range gearing systems, like SRAM Apex. Perhaps most importantly, disc brakes, despite some of their drawbacks, have divorced the rim diameter from the braking equation. This is actually huge news, as it allows one to select tires based less on rim diameter than appropriateness for the intended use. For example, a rider with a hardtail mountain bike can build up an extra set of wheels using 622mm rims to utilize the wide variety of 700x23c tires available in this size. Bottom bracket height still needs to be considered, but as I mentioned before, this is trivial in comparison to tire selection.

OK, so what about cyclocross bikes? These bikes have long been seen by the bike crowd as acceptable hybrids. For mountain bikers, they look an awful lot like a road bike, while roadies see them as a form factor they're comfortable with, just with fat knobby tires. The thing is, of course, that cyclocross is a discipline, with very specific (and arguably arbitrary) rules concerning componentry that cyclocross bike manufacturers have to respect. Despite the fact that the vast majority of cyclocross bikes sold (and, according to reports from Eurobike, [and, one could gather, from this widely circulated cartoon from last year] a lot will be sold this year) will never see cyclocross competition, the buyers of these bikes will have to endure these restrictions as they use their shiny new steeds for commuting or be-fendered winter road riding.

To start with we must address the discipline. Cyclocross racing has about as much to do with trail riding as criterium races have to do with road riding. The arbitrary limitation of tire width to 35mm and the ban on disc brakes has limited the utility of these bikes for consumers wishing to use these bikes for more real-world type conditions. With the new season upon us, of course, the tires have been further limited to 33mm, while the ban on disc brakes has been lifted.

The tire issue is problematic. For those of us with monster-cross builds, or similar 700c hybrids, the issue of quality tire availability in the 35mm-50mm gap has been of serious concern. I'm currently running wire-bead WTB Interwolf 38s, but would love a set of foldables. With the UCI ban on 35s, however, and manufacturers catering primarily to the racing crowd for quality parts I hardly see this becoming a reality in the coming years.

The liberal stance on disc brakes is more promising. As I mentioned before, one of the great benefits of this type of brake is removing the brake from the rim diameter equation. With long-reach caliper brakes, the center bolt of frames intended for 700c wheels have accommodated the suddenly-popular-again 650b wheel size. While at first I was skeptical about the need for this in-between rim size, I can see a greater utility in the tire size when frames are equipped with disc-brake mounts. For example, a cyclocross bike designed for 33mm tires and disc brakes could probably accommodate a much wider 650b tire, even a knobby. This can only be considered a good thing, even if it kind of leaves out all of us with full bike stables and nary a disc brake to be seen.

Friday, September 17, 2010

Exciting times for drop bars

Nowadays handlebar variety has exploded, and with it the simple characterization of bikes into MTB/road categories has fallen apart. Sadly, the old WTB dirt drop bend is no longer available, but there are a wide variety of different bars that fall somewhere in-between your typical drop and your typical flat bar. Even flat bars have gotten interesting thanks to Salsa (17 degree flat bar) and Jitensha studios.

Sadly, though, transmission and braking component manufacturers haven't really kept up. Road-derailleur-compatible flat bar brake/shift levers are easy enough to come by, but the variety of brake levers for operating mountain-style brakes beyond cantis on drop bars has been sparse. May Tr!ckstuff be praised!

Photo from cyclingnews.com.

Photo from cyclingnews.com.This clumsily-mounted chunky widget converts the mechanical pull of your typical drop-bar brifter into hydraulic-line disc brake actuators. More useful for sure than those hard-to-find Magura set ups that only work with their cant-post hydraulics.

Even more challenging than braking from drop bars has been fitting a Rohloff hub shifter, designed for 22.2mm bars. But Mittelmeyer can help you with their reasonably-priced custom shifter.

So it is definitely time to start experimenting with drop bars off road.

Bangatan: singular sports shoe depository

Wednesday, September 15, 2010

Miche Loose Cassette Cogs

As an avid cyclist I've been aware that loose cassette cogs are available from Shimano, but have never given them much thought. This display, at my local shop Veloform, caused me to reconsider the possibilities presented by custom cassettes. These cogs, available from Miche, are suitable for 7-9 speed Shimano cassettes, depending on the spacers used, and are available with grooved, locking top cogs in up to 16t. Considering the 8 speed cassettes I use on all my geared bikes are currently available primarily in configurations starting with an 11 t cog, (yes,there is a very nice 13-26 still around) this opens up the door to a variety of interesting gearing options. My favored 12-28 XTR cassettes are long gone (though IRD makes a similar) but now approximations can be made by hacking existing cassettes and replacing top or bottom cogs.

That the loose cogs stop at 29 may seem a problem to those running mountain bike rear derailleurs, but this can easily be remedied by starting with a stock 11-32 (or 11-34 9 speed) cassette and replacing the top cog with a more sensible 13 or so. I plan to do just this with my monster cross build, paired to a 34/48 up front.

I suspect a lot of folks out there with 10 or 11 speed cassettes are running in essence 8 speed drivetrains, as those tiny top cogs aren't likely to see much action if one doesn't live in a place with long, straight, 8% descents or run incredibly compact chainrings. Reconsidering the composition of the cassette beyond what the manufacturers sell is maybe the single biggest, easiest component improvement you can make to your bike, and displays like the one pictured above present this fact to the consumer in a very approachable and inspiring way.

Hack your cassette!

Adjö, Swedish Penny.

This is a relief, as these coins have long been practically worthless since dispensing machines won't accept them. Really, we're practically a cashless society anyway, with coins being used for almost nothing besides buying bread and paying for parking.

I raided my daughter's piggy bank and liberated this pile of coins: öre on the left, and US pennies on the right. 50 öre is about 7 US cents, so when we're left with 1kr pieces as our smallest denominations, we're looking at having coins in our pocket worth more than the three smallest denominations in the States. So when is the US going to get rid of the near-worthless penny? Ask the nefarious Canadian zinc lobby. And then get used to Swedish rounding.

I raided my daughter's piggy bank and liberated this pile of coins: öre on the left, and US pennies on the right. 50 öre is about 7 US cents, so when we're left with 1kr pieces as our smallest denominations, we're looking at having coins in our pocket worth more than the three smallest denominations in the States. So when is the US going to get rid of the near-worthless penny? Ask the nefarious Canadian zinc lobby. And then get used to Swedish rounding.I counted up 40 50 öre pieces, slipped a 20kr note into the piggy bank, and headed off to the store. 20 kronor bought us 4 ears of corn for dinner.

3D Fabrication: Toys or Tools?

Not surprisingly, Thingiverse, a website for sharing 3D files for printing consists primarily of toys and similar widgets. I suppose the vaunted potential of these devices has slammed up against the hard reality that plastic is a lousy sole material for a lot of things. Giving isolated communities the opportunity to create small parts at will is a great idea, but what sorts of demands can these machines meet? In terms of general hygiene, I suppose various types of combs, brushes, and utensils could be manufactured, as well as specific medical odds-and-ends. For mobility you have dustcaps and maybe some seals for moving parts, but a CNC milling-machine would give you much greater flexibility in the manufacture of small parts. I suppose the machines could be of some use producing educational materials, though teachers are quite resourceful in sourcing and improvising these.

But, as far as toys go, there is great potential in easily and rapidly reproduced small plastic part

s. Exihibit A: the Duplo-BRIO train hybrid brick:

s. Exihibit A: the Duplo-BRIO train hybrid brick:

Rather than creating an entire play system, this solution hacks two commonly available children's toys to create a hybrid perfectly adapted to the end user. The lesson here is to see 3D printing not as a manufacturing revolution entirely on its own, but rather as a vibrant component within an established and effective network of manufacturing and distribution.

A new blog in this day and age?

This blog will primarily function as a vehicle for documenting, sharing, and organizing information relating to lifestyles, politics, sustainability, tools and material culture, and modern homemaking (homing). It will double as an outlet to express opinions on these topics and hopefully triple as a forum for discussing these matters. But you all know what blogs are.